Li-coolers tsa oli tse sebelisoang tsamaisong ea hydraulic

Libaka tse ling tsa soradiator li koahetsoe.Ka lebaka la bokhoni ba eona ba tlhahiso ea setsebi, soradiator e hlahisa lihlahisoa tse ngata.E kenyelletsa li-coolers tse nyane tse sebelisoang lits'ebetsong tsa hydraulic.Sehlahisoa sena se na le litšobotsi tsa boholo bo nyane le ho hanyetsa khatello e phahameng.Lintlha tsohle li bonts'a ts'ebetso ea tlhahiso ea siradiator e phahameng haholo.

Li-coolers tse nyane tse sebelisoang lits'ebetsong tsa hydraulic ke lisebelisoa tsa mocheso tse kopaneng tse etselitsoeng ho tlosa mocheso o feteletseng ho tsoa mokelikeli oa haeteroliki.Ka tloaelo li na le letoto la li-tubes tsa tšepe kapa lipoleiti tse fanang ka sebaka se seholo sa holim'a metsi bakeng sa ho fetisa mocheso ka katleho.Mokelikeli oa hydraulic o phalla ka har'a li-tubes kapa lipoleiti tsena, ha mokhoa o pholileng, o kang moea kapa metsi, o feta holim'a bokantle ba ka ntle ho felisa mocheso.

Li-coolers tsena tsa oli hangata li na le mapheoana kapa li-turbulator holim'a bokahare ba li-tubes kapa lipoleiti ho matlafatsa phetisetso ea mocheso.Lithako li eketsa sebaka se ka holimo se fumanehang bakeng sa phapanyetsano ea mocheso, ha li-turbulator li senya ho phalla ha mokelikeli, ho khothalletsa ho kopanya hantle le ho fetisetsa mocheso.

Li-coolers tse nyane tsa oli hangata li kopantsoe le potoloho ea sisteme ea haeteroliki, ekaba li-unit tse ikemetseng kapa e le karolo ea pokello ea pokello ea metsi kapa ea mocheso.Li thusa ho boloka mocheso o nepahetseng oa ts'ebetso ka ho thibela mokelikeli oa hydraulic hore o se ke oa chesa haholo, o ka lebisang ho fokotseng ts'ebetso ea sistimi, ho roala likarolo, le tšenyo e ka bang teng.

Lipholi tse ling tse nyane tsa oli li kanna tsa kenyelletsa likarolo tse ling, joalo ka li-valve tsa bypass kapa lisensara tsa mocheso, ho laola phallo ea mokelikeli kapa ho hlokomela mocheso o sebetsang.Li-coolers tsena li tla ka boholo le litlhophiso tse fapaneng ho lumellana le litlhoko tse fapaneng tsa sistimi ea haeteroliki, tse fanang ka pholiso e sebetsang ka moralo o kopaneng le o bolokang sebaka.

Bakeng sa li-radiator tse ling tse tloaelehileng, soradiator e na le workshop ea eona ea machining, e ka finyellang litlhoko tsa tloaelo ea bareki ka botlalo.E ka etsoa ka botlalo ho ea ka tikoloho, khatello, bolelele, nozzle, molumo oa moea oa moea, sekhahla sa phallo, ho hanyetsa ho sisinyeha, boholo ba ho kenya, thebe e sireletsang, joalo-joalo e hlokoang ke bareki.

Ka nako e ts'oanang, e ka boela ea hlahisa li-radiator bakeng sa mechine ea temo le meru.Mofuta ona oa radiator o na le litšobotsi tsa ho kopanya mesebetsi e mengata.Radiator e pholile ka metsi ka lehlakoreng le leng 'me ka lehlakoreng le leng e pholile ka oli.Ha e ntse e netefatsa hore e sebetsa hantle, e hatella sebaka haholo.

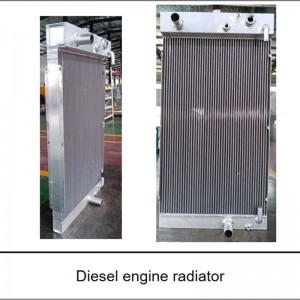

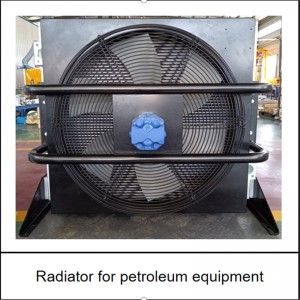

Ho boetse ho na le li-radiator tse sebelisoang lienjineng tsa diesel.Li-radiator tse sebelisoang lisebelisoa tsa peterole, li-radiator tse ling, joalo-joalo.

E kenyelletsang ts'ebetso e ntle ea soradiator ea argon arc welding.Mohloli o mong le o mong oa soradiator o na le litsebo tse ntle haholo tsa ho tjheseletsa argon tse bokelletsoeng ka lilemo tse fetang leshome.E ka netefatsa boleng ba welding le ponahalo ho isa tekanyong e kholo.Bakeng sa lihlahisoa tse nang le khatello e phahameng, soradiator e amohela theknoloji ea core chamfering + ho kenella ka hare ho welding + welding ea li-pass tse peli ka nako e le 'ngoe.Tekanyetso ena ea taolo ea welding e ka netefatsa boleng ba khatello ea welding ea lihlahisoa.Sekhahla sa pele sa ho feta sa teko ea ho tiea ha khase ea argon welding e ntse e le ka holimo ho 92%.

E ntlafalitsoe ho ipapisitsoe le bokhabane ba thekenoloji bo etelletseng pele 'marakeng, mefuta e fapaneng ea Cooling Modules bakeng sa lisebelisoa tsa kaho e amohetsoe butle-butle ke bareki ba nang le boleng bo netefalitsoeng ke' maraka.All-in-one Cooling Module e etsa hore moea o phalle hantle ka ts'ebetso e phahameng ea ho fapanyetsana mocheso le nako e telele ka lebaka la motsoako oa Bar & Plates.

Lisebelisoa tsa mocheso li hlahisoa ka thepa e kenyeletsang aluminium le li-coopers, bakeng sa maemo a khethehileng a ho sebetsa.Li-Modules tsa ho Pholisa Temo le tsona li entsoe ka motsoako oa Bar & Plate.