li-coolers tsa oli tsa hydraulic

Li-coolers tsa oli ea Hydraulic ke lisebelisoa tse sebelisetsoang ho laola mocheso oa mokelikeli oa hydraulic tsamaisong ea hydraulic.Li thusa ho boloka mocheso o nepahetseng oa ts'ebetso ka ho lahla mocheso o hlahisoang nakong ea ts'ebetso ea sistimi.Li-coolers tsa oli ea Hydraulic hangata li na le letoto la li-tubes kapa mapheoana a eketsang sebaka sa ho fetisa mocheso.Ha mokelikeli o chesang oa haeteroliki o phalla ka sehatsetsing, o fapanyetsana mocheso le moea o potolohileng kapa sebaka se arohaneng sa ho tsidifatsa, joalo ka metsi kapa mokelikeli o mong.Ts'ebetso ena e kokobetsa mokelikeli oa hydraulic pele o khutlela tsamaisong, ho thibela ho chesa le ho netefatsa hore tsamaiso e sebetsa hantle.

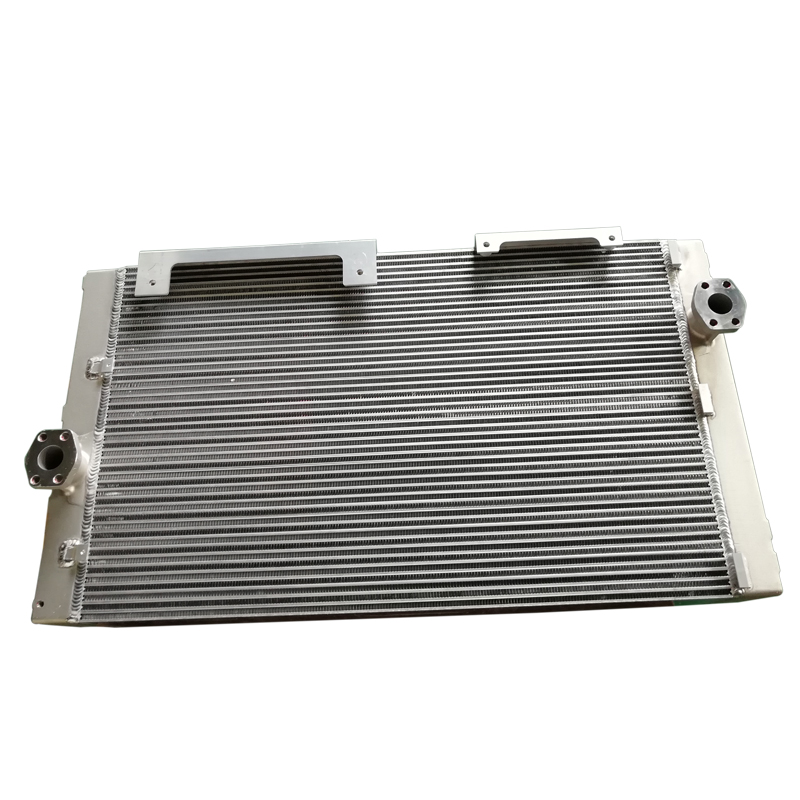

Nka mohlala oa hydraulic system, thepa e hloka ho boloka khatello e phahameng e sa khaotse ha e sebetsa, e tla hlahisa mocheso o mongata, 'me mocheso oa oli o tla phahama ka mor'a nako e telele ea mosebetsi.Haeba mocheso o sa lokolloe ka nako, o tla lebisa botsofaling le tšenyo ea likarolo tsa tiiso ea tsamaiso, 'me viscosity ea oli e fokotseha ka ho phahama ha mocheso oa oli,' me khatello ea oli e ke ke ea finyella litlhoko. tsa mosebetsi.Ho netefatsa ts'ebetso e bolokehileng le e tšepahalang ea lisebelisoa.Mocheso oa oli o tlameha ho laoloa ka har'a mefuta e behiloeng.Lebaka le ka sehloohong la ho phahama ha mocheso oa oli ea tsamaiso ea lubrication e fapane le ea tsamaiso ea hydraulic, empa ho boetse hoa hlokahala ho laola mocheso oa oli oa oli e tlotsang ka har'a mefuta e behiloeng.'Me karolo e jereng boikarabelo bona ke sepholi sa oli.Sepholi sa oli se sebelisoa haholo ho pholisa oli ea haeteroliki le oli e tlotsang;Oli e pholileng e sebelisoa haholo mecheng ea polasetiki, mechini ea boenjiniere, mechini ea merafo, koloi, tšepe, matla a moea, sefofane le liindasteri tse ling.Ho na le mefuta e mengata ea sepholi sa oli, se ka aroloa ka mofuta oa li-tube le mofuta oa mapheo a poleiti.Ha ho bapisoa le mofuta o pholileng oa oli oa mofuta oa tubular, mochini o pholileng oa oli oa mofuta oa plate-fin o ka mamella khatello e phahameng ka lebaka la litšobotsi tsa ona tsa sebopeho.Sena se etsa hore oli ea mofuta oa plate-fin e pholile e sebelisoa haholo ho fehla matla a moea, sistimi ea haeteroliki, terene ea terene le masimo a mang.

Soradiator e tsepamisitse maikutlo haholo ho nts'etsopele le nts'etsopele ea mochini o pholileng oa mofuta oa plate fin.Kamora lilemo tse fetang leshome tsa tlhahlobo le nts'etsopele, ho thehile mohala o tiileng, o sebetsang hantle, o phahameng, oa boleng bo holimo, o tenyetsehang oa tlhahiso ea li-radiator.Baenjiniere ba lula ba ntlafatsa le ho ntlafatsa ts'ebetso ea tlhahiso.Ho tloha ho bataletseng ha karohano, sebopeho sa mapheo, litekanyetso tsa ho hloekisa, ts'ebetso ea kopano, theknoloji ea tjheseletsa ea vacuum le taolo ea nako, teko ea ho tiisa moea, plug welding, e thehile sete ea litekanyetso tse tsoetseng pele haholo le tsa saense tsa tlhahiso.Sekhahla sa ho feta ha nako e le 'ngoe sa plate-fin core se fihla ho feta 99%.Ka nako e ts'oanang, bahlahisi ba Soradiator ba ka fetola sebopeho sa mapheo, boholo ba mapheo le khatello ea khatello ea radiator ho ea ka litlhoko tsa thepa le litekanyetso tse fanoeng ke bareki, e le ho hlahisa lihlahisoa tse loketseng ka ho fetisisa bakeng sa bareki ho finyella litlhoko tsohle. ea bareki bakeng sa radiator ea mofuta oa plate fin le sepholi sa oli.